A new initiative between Network Rail and South Western Railway has more than doubled the number of trains treating the railway and keeping the tracks leaf-free this Autumn.

In a first for the railway across the south of England, a SWR-inspired and Network Rail-funded project to improve rail adhesion has seen 39 SWR Class 158 and 159 trains retrofitted with specialist technology that applies sand to the tracks to help improve wheel grip during the wet and slippery autumn and winter months.

The technology, developed and fitted by Siemens Mobility, is an upgrade to existing sanding mechanisms already fitted on some trains, by providing a more efficient sanding application that releases sand at a variable rate dependent on the speed of the train and condition of the tracks.

These new, advanced sand applicators can distribute up to 5kg of sand onto the tracks per minute, and automatically apply sand when a train is braking. As a result, the distance it takes a train to stop is significantly reduced.

SWR’s fleet of Class 158 and 159 trains is diesel-powered and generally runs on parts of the railway that do not have the electrified third rail, such as the West of England Line, which connects Waterloo to Exeter, the Romsey area, and occasionally between Salisbury and Reading.

Between October and December every year, roughly 500 billion leaves weighing around half a million tonnes fall onto the railway. They stick to damp rails, and passing trains crush them into a thin, hard layer on the rail, which, like black ice on the roads, can affect braking and acceleration.

Neil Drury, South Western Railway Engineering and Infrastructure Director said: “The new sanding system for our fleet of Class 158 and Class 159 trains will improve safety and help keep our services running on time in some of the most challenging conditions for the railway.

“Our engineers have done a brilliant job to efficiently install the system on all 39 of our trains and get them back out on the network to serve customers. The results show a clear difference compared to the previous sanding system, halving the stopping distances on slippery rails.

“Our partnership with Network Rail and Siemens Mobility is a great example of how the rail industry can come together and improve safety and performance.”

Sambit Banerjee, Joint CEO UKI, Siemens Mobility, said: “We are delighted to see our cutting-edge Variable Rate Sanding technology being installed on 39 of the Class 158/159 units for SWR and reaching the milestone of going into passenger service.

“This innovative technology optimises the rate at which sand is spread, significantly enhancing braking performance in challenging conditions, like wet conditions or autumn leaves on the line, enabling braking performance almost matching dry conditions. With a target braking force of 4%g, the SVRS system consistently achieved above 5%g braking in all scenarios in testing.

“This has been an excellent collaboration between SWR and Network Rail, underscoring our combined commitment to improving rail safety and we are grateful to have been supported by research from the Rail Safety and Standards Board (RSSB). This is a great achievement for the innovation team at Siemens Mobility, and the technology was Highly Commended at the National Rail Awards, being recognised as having great potential for trains across the whole UK railway.”

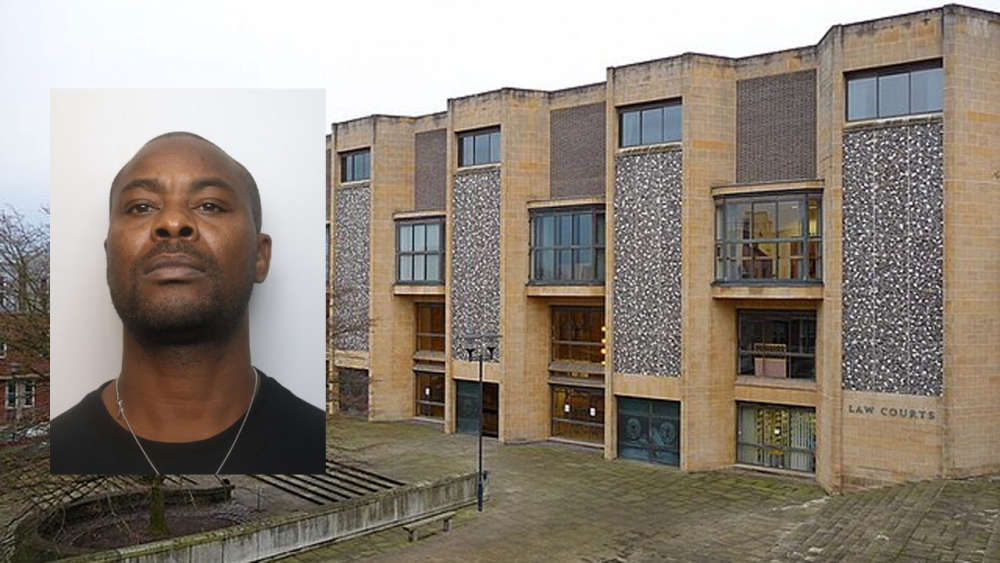

Man jailed for almost twenty years for multiple sexual offences against child

Man jailed for almost twenty years for multiple sexual offences against child

Man sentenced for breaching Criminal Behaviour Order in Salisbury

Man sentenced for breaching Criminal Behaviour Order in Salisbury

New Stars Appeal equipment helps 2,000 extra heart patients in first year

New Stars Appeal equipment helps 2,000 extra heart patients in first year

Salisbury travel to take on Boreham Wood as league survival quest continues

Salisbury travel to take on Boreham Wood as league survival quest continues

Multiple Pairs of Sunglasses stolen from Amesbury shop

Multiple Pairs of Sunglasses stolen from Amesbury shop

Salisbury woman to run marathon in honour of dad who survived tumour the size of a rugby ball

Salisbury woman to run marathon in honour of dad who survived tumour the size of a rugby ball

Salisbury District Hospital tops national survey

Salisbury District Hospital tops national survey

Man jailed for 28 months following stabbing in Amesbury

Man jailed for 28 months following stabbing in Amesbury